205/595-6455

HERConsult@aol.com

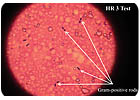

The dairy industry loses millions of dollars every year from product deterioration caused by spoilage bacteria. Spoilage bacteria result in shorter shelf life and decreased quality for milk products. By identifying the specific types and numbers of microbes involved, we can improve shelf life and quality by reducing bacterial contamination. While various tests have been developed to "estimate and identify" spoilage bacteria, a series of dye reduction procedures has proved to be particularly useful. A brief explanation of each test follows:

Negative results for both tests (HR-1 and HR-2) indicate effective sanitation practices on the pasteurized side and the potential for excellent keeping quality. However, if actual keeping quality (45°F for 14 days) is not consistent with the negative test results, spoilage is likely related to the presence of heat-resistant, spore-forming bacteria.

Join Dr. Randolph and Associates in Birmingham, Ala. for an in-depth Dairy Technology Workshop May 1-4, 2006. For registration information, contact Kristy Clark: 205/595-6455 or e-mail kmclark@randolphconsulting.com.