For nearly forty years the plant has been converting raw milk into dairy products. For the past nine it has been producing fluid products including International Delight and private label dairy and non-dairy coffee creamers for distribution throughout the central U.S. and coast to coast. Most recently the plant also became the home of regional distribution center for Morningstar and Dean Foods products. Mixed orders of private label and branded products are now available for direct customer pickup or shipment.

“We have a mix of Dean’s and Morningstar products,” says Plant Mgr. Joe Wallace. “Basically every kind of product that Morningstar distributes is now coming though our facility.”

The $5 million DC project began in January 2002 and ended in September. The result is a 55,000 sq ft. facility that holds 5,000 pallets, that serves much of the central part of the country.

Prior to the project’s completion, much of the plant’s storage and logistics was outsourced to a private cold storage facility in Dallas, and the 14,000 sq. ft. of on-site storage had to be augmented with refrigerated trailers.

The new DC is the first of three that Morningstar has constructed almost simultaneously to better serve its customers, says Bing Graffunder, chief operating officer.

“As we’ve grown, we’ve introduced an increasingly complex matrix of SKUs on the brand name side of the business, and we still have a big stake in private label business,” Graffunder says. “We’ve constructed this DC to enable our customers to be closer to that full spectrum of products.”

Two similar projects, in Southern Calif., and near New York City, are about 60% complete, and the company may soon look to other markets for citing additional centers.

“Historically we have used outside public warehouses,” Graffunder explains. “As we come out of those facilities we are reducing the number of warehouses we use and concentrating product in a smaller number of places.”

Upgrading for efficiency

The DC has refrigerated space for 2,500 pallets of extended shelflife (ESL) products, and a climate-controlled warehouse that holds up to 2,400 pallets of aseptic products. It’s also highly automated.“One big thing that’s changed is the software for the warehouse management system,” Wallace says. “We’re using an ASC track bar code system. Each pallet spot has a number and the system tells you where to put the product. When you are picking product it sends you to the lowest code and in that way it manages your inventory. Accuracy and efficiency are the reasons we installed the system.”

The storage systems also use newer technology. “The majority of the pallet and racking system is push-back racking,” Wallace says. “We use a combination of forklifts, reach trucks and standup pallet jacks.”

To minimize traffic and improve efficiency, storage was designed with high-pick items toward the shipping dock. The warehouse is cooled with Freon on both the climate-controlled and refrigerated side, and there are 11 load-out doors in the new building. Commercial Services Inc., Sulphur Springs, served as the A&E and construction firm for the project. The Sulphur Springs plant produces a variety of products including branded and private label creamers, half & half, chocolate milk, whipping cream and table cream. The plant’s six lines have the capacity to produce more than 12 million lbs of product a month.

“Our production only accounts for about half of what goes through the DC,” Wallace says. “The other half is yogurts, sour creams, dips, dressings, aerosols—everything Morningstar produces out of the other facilities.”

The DC operation brought to the plant 18 additional jobs, despite some level of automation. The processing and distribution facilities now employ a total of 151 people.

From humble beginnings

Built in 1965, as the Lamar Creamery, the plant originally consisted of 13,500 sq feet used for fluid dairy processing. The plant was acquired by the Southland Dairies Group in the early 1970s and at one point was used primarily for juice and cultured products.“The plant has continued to grow, really over the past 38 years,” Wallace says. “The company has put a lot of capital into this plant, especially over the last ten years.”

The first aseptic line was added in 1994, and as more aseptic and ESL lines were added, the juice and cultured manufacturing was phased out. A second Bosch filler was added in 1997 and a third in 1999.

The aseptic lines run seven days a week, and the ESL lines run six days a week. Raw milk is delivered daily and tested in an on-site lab. Milk is procured almost exclusively from Dairy Farmers of America, Kansas City, Mo.

Raw milk and cream is stored in seven silos with a total raw storage capacity of 136,000 gal. There are seven ESL blending tanks ranging in size from 1,500 to 10,000 gal. Five aseptic tanks range in capacity from 3,000 to 5,000 gal.

Three liquifiers are used for blend-_ing products.

The processing plant is really two plants in one, with three ESL lines and three aseptic lines. UHT processing for the ESL lines is done with two direct steam infusion systems rated 2,100 and 1,750 gal per hour. Product is briefly heated to 285¿ F on the UHT system.

The aseptic side features two tubular indirect heating and cooling systems rated at 740 and 710 gal per hour. Here the product is also heated to 285¿ F, but the temperature is held longer. Both systems have been custom fabricated as the plant has grown and both include some components from APV.

Once product is filled it is placed in corrugated secondary packaging for palletizing. A new Fanuc robotic palletizer installed at the plant in 1999, is used for aseptic products.

In the new DC, orders are picked and readied for delivery via Morningstar’s distribution network, or drop-shipped to a customer’s own distribution hub. Some customers take delivery of orders directly from Sulphur Springs.

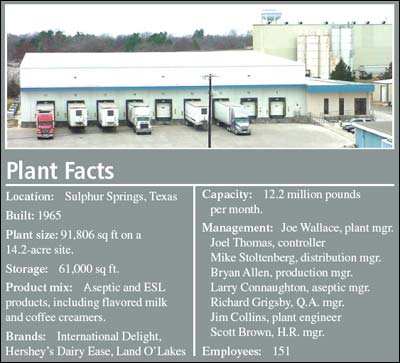

The plant sits on a 14.2-acre site, and there is just less than 92,000 sq. ft. of manufacturing space. Other plant features include a power plant with two boilers producing a total of 500 horse power. An ammonia plate chiller is used for cooling along with 15,500 lbs of ice bank capacity. Nine ammonia compressors have a total capacity of 658 tons and two condensers are rated at 362 and 215 tons.